News28 November 2024

Padoan featured in October issue of We are access equipment

A factor you can’t underestimate

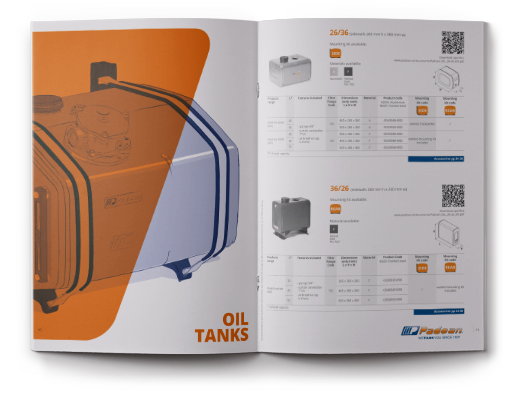

The quality of the tank related to raw material, cleanliness, processes such as robotic welding and quality controls, make this container full of meaning and functionality.

The tank, in several cases, is an issue to be dealt with in the last step of designing a machine or an industrial vehicle application. It is sometimes a paradoxical situation because, aside from the mechanical parts required for motion or propulsion (depending on the hydraulic or fuel/combined tank), it is the tank that stores the fluid or liquid that is required to operate the system. The quality of the tank is therefore crucial, since the tank is the entity to which the system is connected in and out. This leads to the definition of suction connections, returns, drains, filters, and accessories that can be an integrated part of the tank to facilitate day-to-day operation while taking care of the system’s longevity, thus becoming organic solutions, not mere

components.

The different versions

In this field, the decision to develop ‘Dual’ models (for hydraulic oil) guarantees the possibility to use the same tank body either side-mounted or on a flat surface, simply by changing the mounting kit, thus facilitating at the same time the operative management of manufacturers, bodybuilders and distributors. The range of hydraulic tanks developed by Padoan has a minimum capacity of 30 l, suitable for small vehicles and machinery, reaching 400 l in full. The range of components is such that plug&play solutions can be delivered, which once unpacked are ready for installation.

The same concept applies to diesel tanks (from 60 to 960 l) and combined tanks that integrate the oil and diesel partition in a single tank body. Here too, the accessories play a key role, particularly as they have been developed to ensure a complete solution.

Attention to detail

Thanks to the technical knowledge developed over time, one of Padoan’s must-haves is the characteristics of the sidewalls of the tanks, with proportions and dimensions that ease the flow of the fluid and that, particularly for oil tanks, guarantee useful characteristics for heat dissipation.

They are manufactured in aluminium, epoxy powder-coated carbon steel (possibly with primer application) and stainless steel. The latest material is, unquestionably, the solution for particularly aggressive environments and extreme working conditions.

Download our

company brochure

Discover our catalogue, with all the detailed information about our products.

Download PDF